It’s no secret that the availability of CNC fabrication opens a lot of doors for the design community, but how will it effect the next style movements?

The high-design world currently lives in a world that’s built on minimalism. No flash, no extraneous detail and the precision of shape. To see where tomorrow’s styling is going it’s important to understand how we got to this world of “Modern” that’s defined as “minimalism”.

Going back to just after the turn of the last century, we record a sea-change in the way the world styled things. If one focuses on only the International Style or Bauhaus that minimal style was created for the idealistic purpose of creating products so that all in society could achieve the same level of comfort. To remove a lot of the detail work was a primary method, in their minds, that would allow for the every-man to have such things we think of as common, like refrigerators, more furniture, tableware and various kitchen items of the so-called modern world.

How much cheaper would a coffee pot be if it wasn’t made by craftsmen that inscribed and forged them into intricate shapes? They would be cheap enough for anyone to own as they’d be easy to make with a simpler manufacturing process. So too was the thinking behind the tube-framed furniture of LeCorbusier and Eileen Gray. Instead of time consuming labor done by craftsmen, a sofa could be formed with modern tools by certainly less skilled workers. This would drive down the cost of a couch to approach-ability.

While the aim of modern was admirable, their goals sadly did not translate to the real world. Modern became expensive and aimed at the exact group it was not designed for. We now associate clean lines and a desert of detail to “Modern”.

Only relatively recently has the world seen the true manifestation of the original desires for modern design. The companies leveraging these traits are companies like Target and IKEA. The lack of ornamentation works insanely well at reducing costs. This reduction has made living in the modern world relatively easy. But what now happens with design?

There can be no more subtraction, there must now be addition.

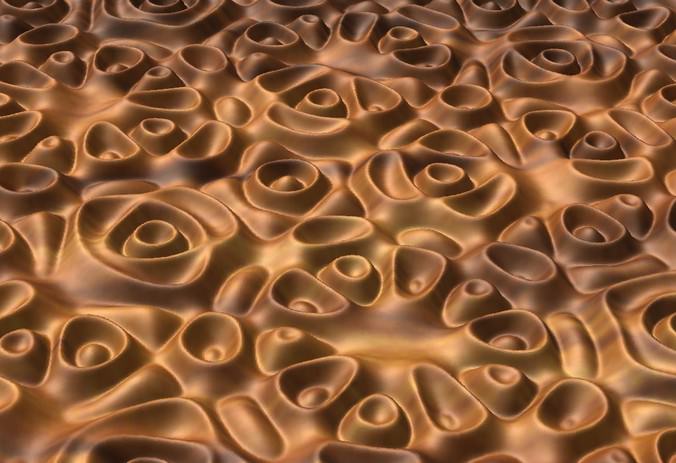

New tools like CNC machining has now opened the door for designers to more easily employ ornamentation into custom or low-count production runs. It’s also opened the door for the implementation of styling and design complexity far beyond what craftsmen can do – or more importantly – what we can afford craftsmen to do. Couple this with the notion that at a certain point simplification of designs can only go so far before there is no difference between designers and ornamentation becomes almost a necessary adaptation.

The new ornamentation will once again bring massive personalization but will require processes that can keep up. This will fall to digital fabrication processes where designers can design digitally and send these to firms to contract manufacture the results. Machines like CNC Mills and Lathes will be necessary to achieve the new design and styling intents.

At a certain level, there will be cottage industries of designers with CNC Mills in their shops, but there will also be the need for larger-scale implementations as designers tire of having satisfy the demands of designing and of operating complex machinery. But in the end, ornamentation will be reborn in the high-end design space, even if it’s manufacturers have given up the old ways of manufacturing items.