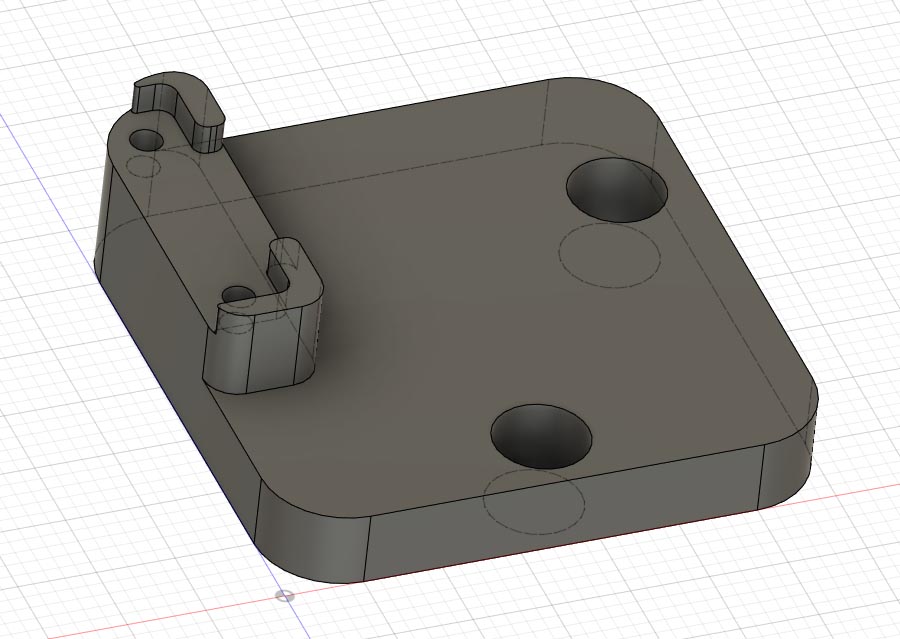

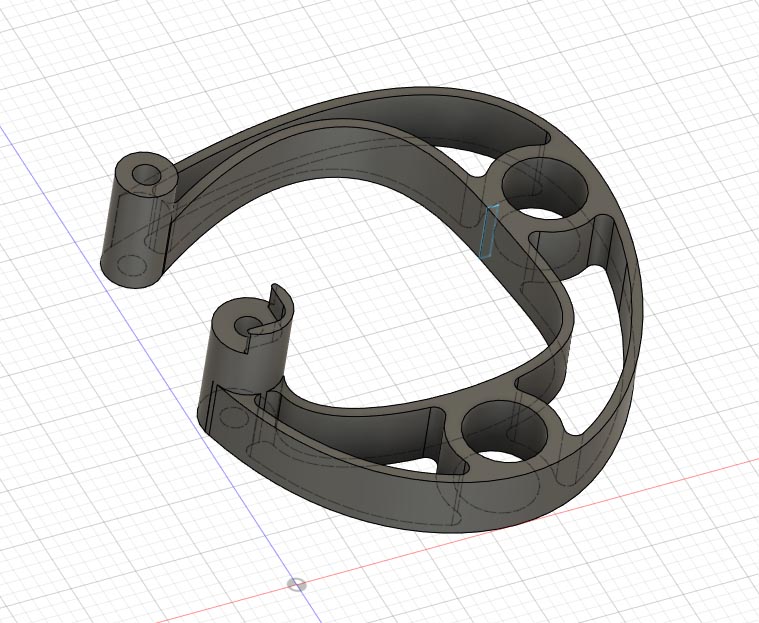

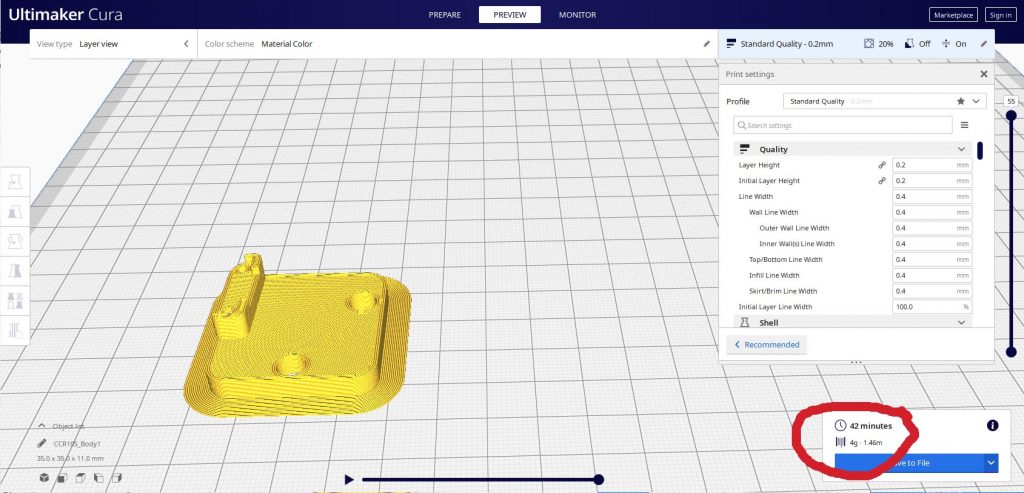

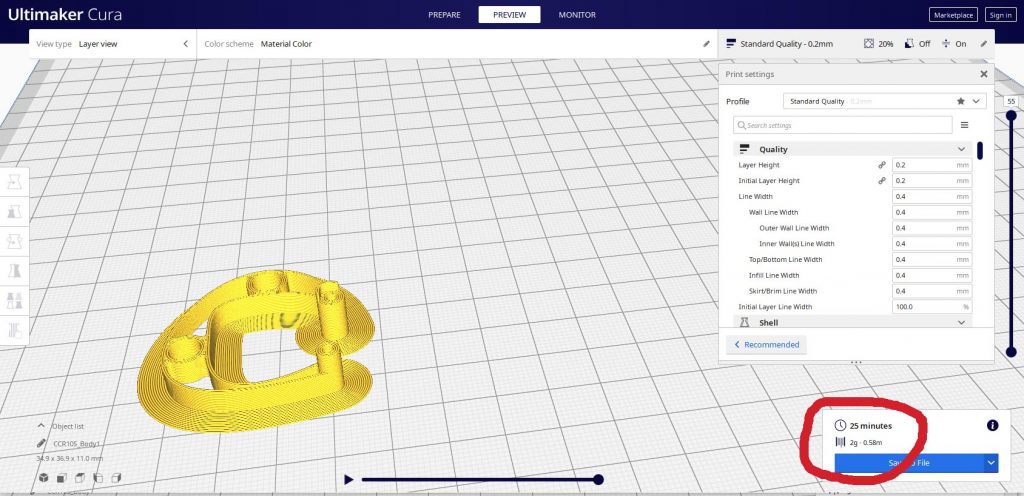

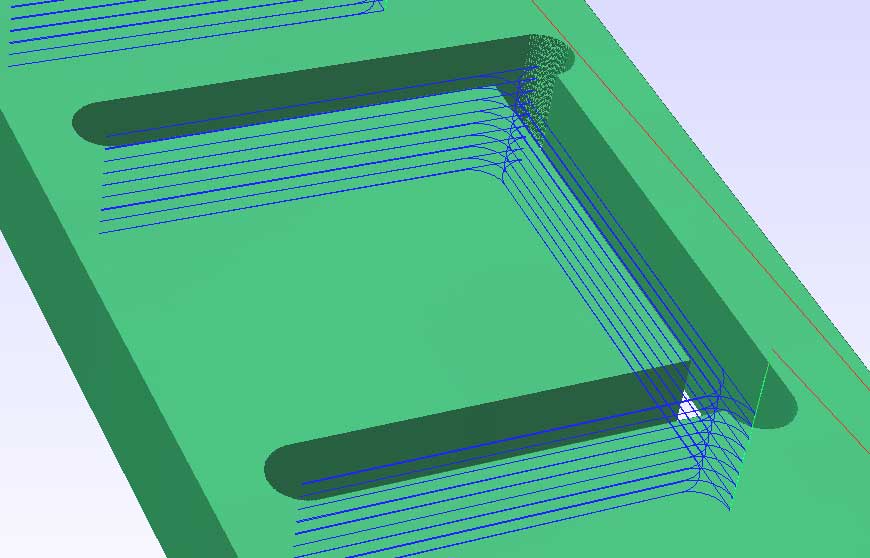

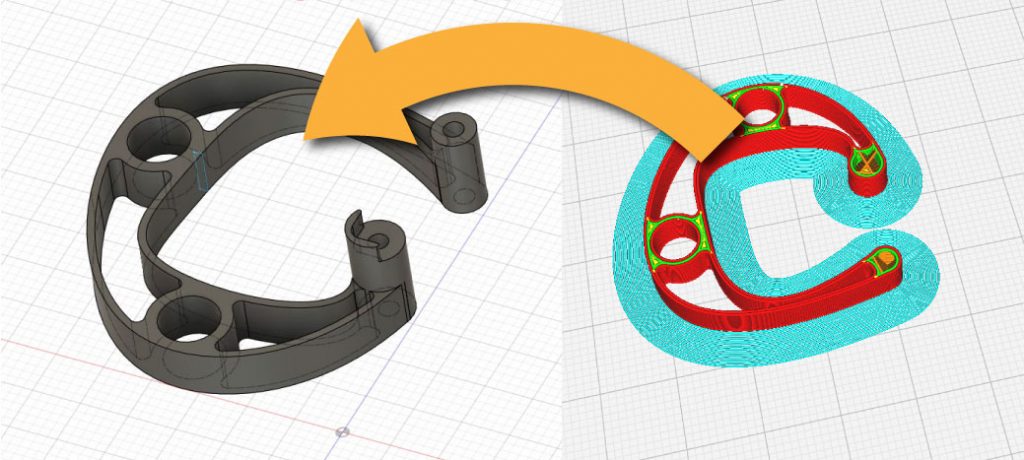

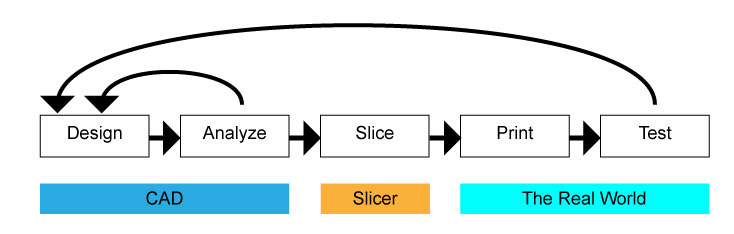

While there are others working on something more integrated, for everyone else the part design and 3D printing process is a two step affair: design the part in some CAD software suite then export the part to a slicer to create the file needed to print. The first step is where the outer aspects of the part are developed – the overall shape and the features of the part, etc. The second step is where the features the 3D printing process needs to be successful are developed – including the layer counts, the configuration of the part within the printer and the infill.

It’s obvious why this division of operations developed the way it has. In the beginning, CAD software was built for subtractive operations and at the time it had virtually no functionality for printing items. The additive community had to develop software to translate the CAD files into the gCode to operate on the then nascent technology. That created the process of making your shapes in CAD, exporting it to a file that could be loaded into that specialized 3D printer file, a slicer, to be transformed into the required gCode.

The above was perfectly fine for getting the 3D printing industry started by making a complex process relatively easy to perform. Now, we live in the future.

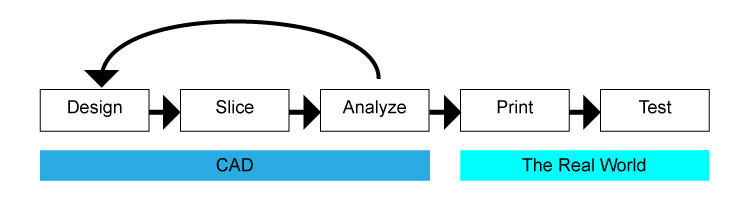

In order for 3D printing to really make an impact, it needs to have software built to take advantage of the process. That means we need to have the right processes in the correct stage of the design-print chain. We need to have infill selection, configuration and design in the CAD side of things.

For now

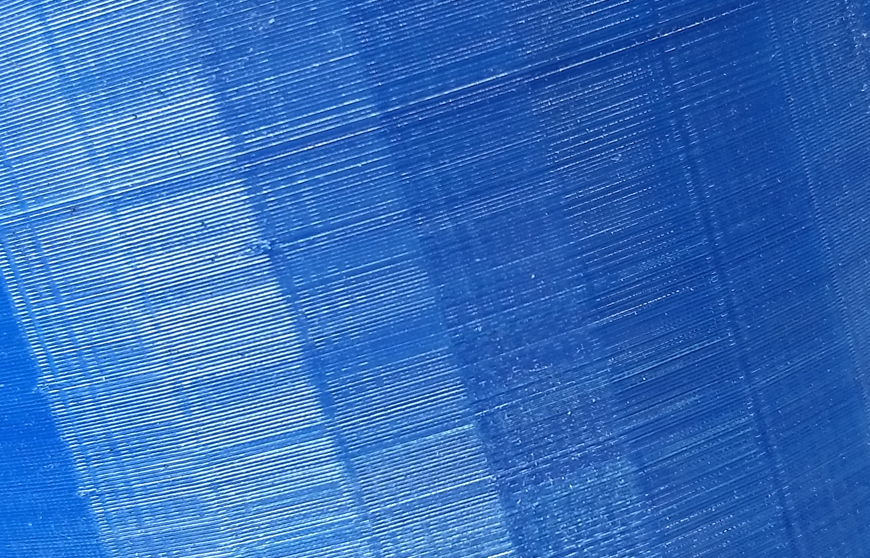

Why? The reason is the infill helps provide the mechanical characteristics of the material used and the designed shapes themselves. The infill helps determine the strength of the part, the mass of the part and perhaps even the flexibility, distribution of said mass and perhaps even characteristics of heat dissipation and other advanced aspects.

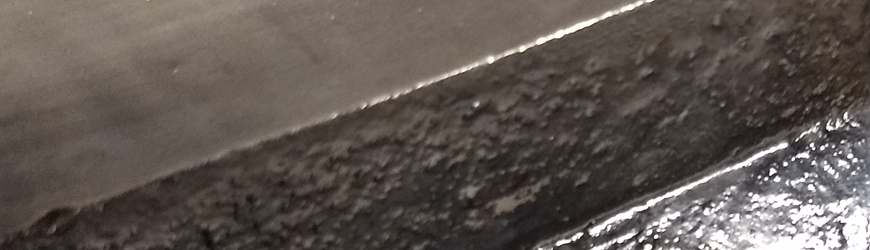

If the designer is relying on the CAD software to provide some of these calculations – either through the basic functionality of the CAD suite itself or exporting models to more advanced analysis tools, those numbers will be based on a solid material, rather than a lattice material within a shell casing. In short, the numbers will not correspond to the printed part. Perhaps this might not be much of an issue for lightweight plastic not being called into service on something high performance, but for metals, it can be an issue. What’s more, this separation of infill and design disallows designers to truly maximize material usage because the testing is well before and completely disconnected from the slicing stage. The designer will have to over-engineer a part just to make sure it operates properly, or rely on testing of the printed part afterwards to dial in the infill and sometimes even the designed shape’s characteristics to guarantee proper functionality.

For the future

If we really want to capitalize from the capability of Additive Manufacturing, then that will only come from having complete design authority over the part at the design stage. Moving infill into the design stage opens opportunities to begin thinking about the advantages of being able to tune the infill for specific tasks.

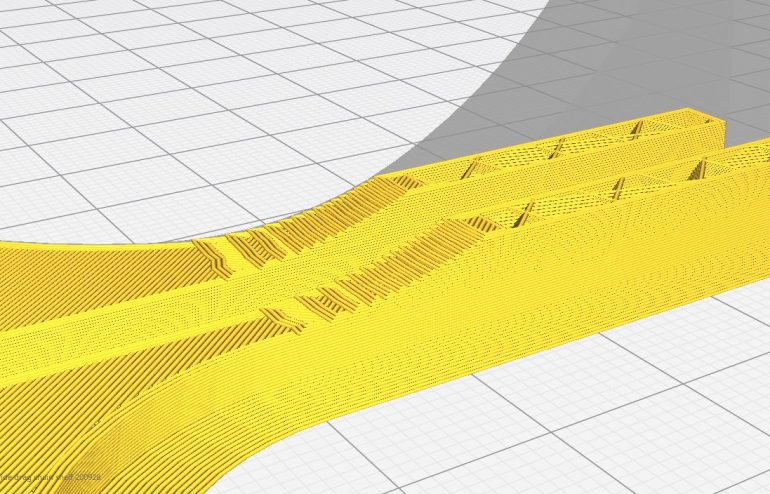

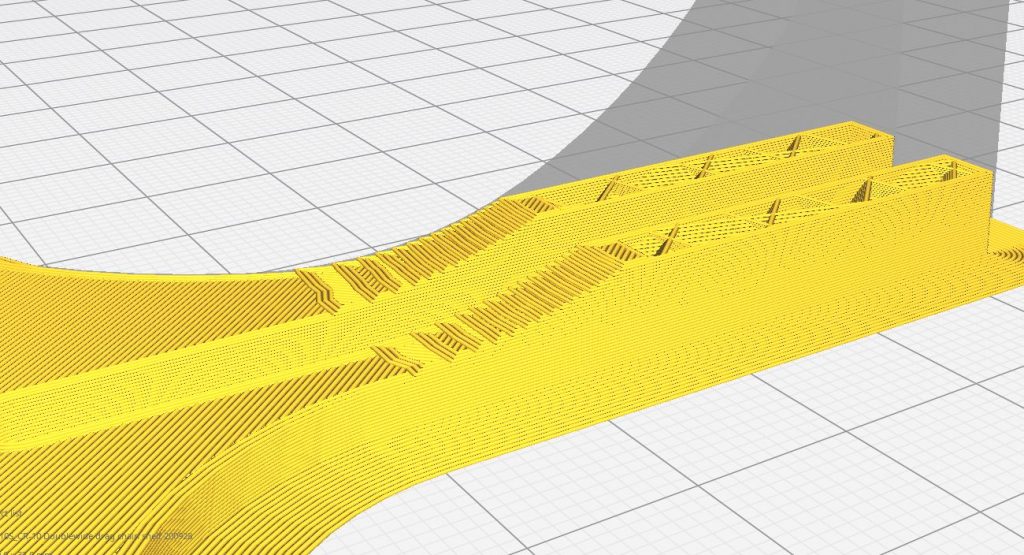

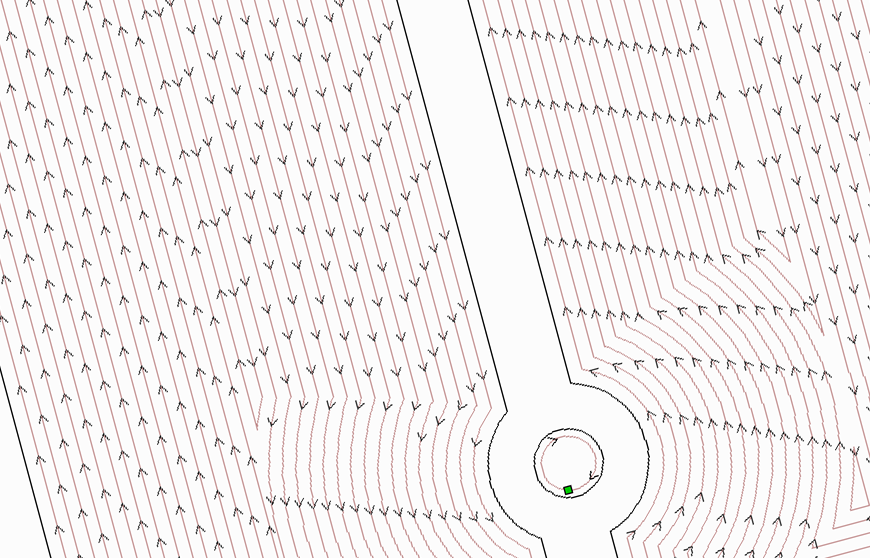

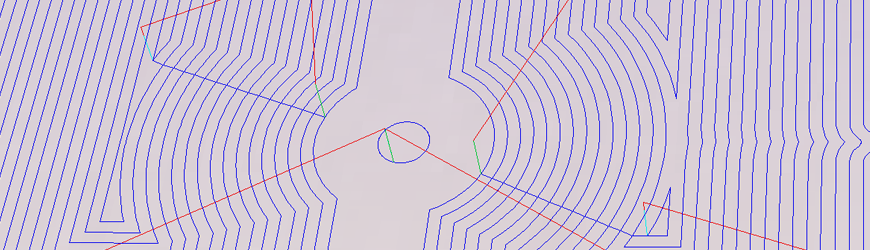

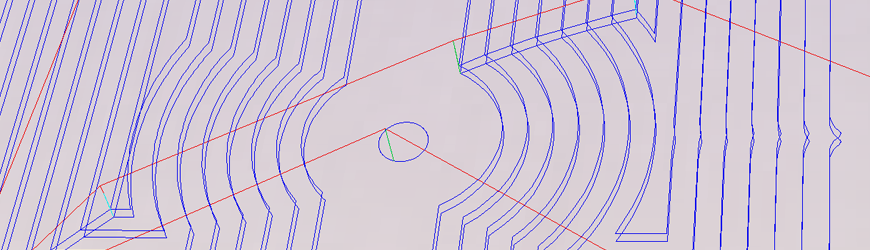

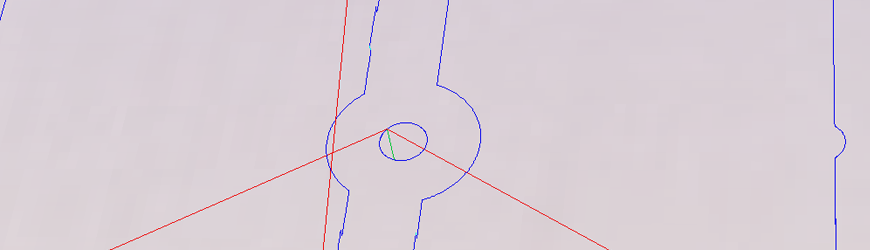

With the right tools, designers can push infill from a homogeneous pattern into ones that integrate the part’s use case – from the inside out. The pattern could change and become more dense in certain areas and directions where it is critically needed and significantly lessened where it is only marginally needed. Perhaps the infill pattern could be designed in such a way that it could allow flexibility in one direction and high rigidity in another according to the conditions the part needs to operate in. Maybe the infill could be designed to absorb or even channel heat within the part more effectively.

While the above are just a few examples, they quickly highlight the potential that could be unlocked when infill is designed within the part development process rather than purely considered a function of gCode construction.