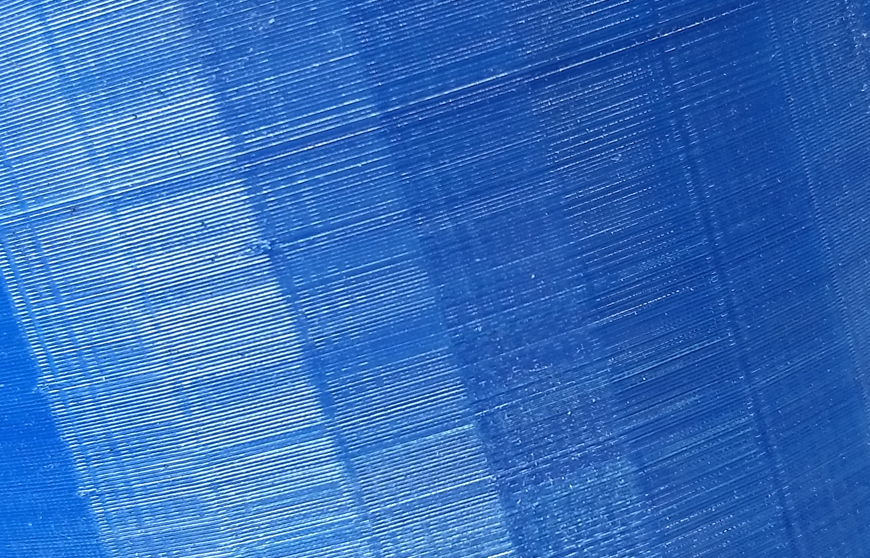

It seems the surface finish of 3D printed parts continues to be a pretty big deal, especially in FDM printing. Let’s be a bit more specific about finish and aim at the aesthetic aspects while setting aside functional issues regarding finish.

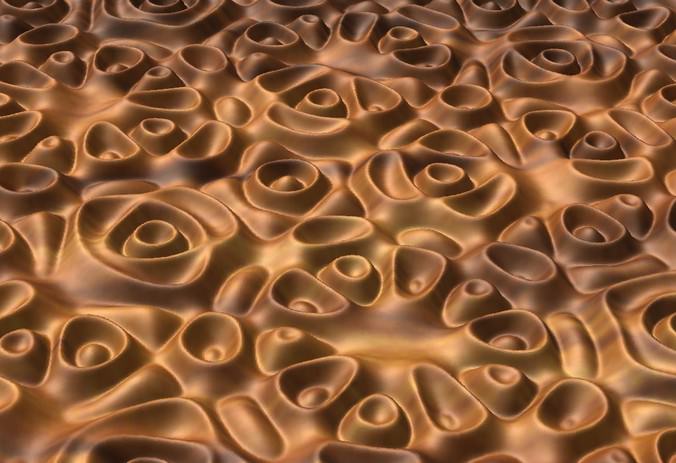

Back in college, I wrote a little opinion piece about the seeming draw of – or at least ambivalence to – contemporary shoppers to faux finishes. Everything from hubcaps to fake plants were used to support the notion. While the argument might be fun to rehash, today we could easily feel comfortable saying most of us are really not aghast of materials aping other materials. We’ve become comfortable to the point where we don’t even consider that the surface finishes in our cars are supposed to be approximations of more expensive materials like leather or wood represented in plastic. We’ve also have allowed veneering to uplift substandard materials in our furniture – and even have looked a blind eye to now using plastic-based, printed veneer to take the place of real, natural veneers. The feel of Formica and Corian is just as common and accepted as marble countertops and sometimes preferred.

These previously aesthetically abhorrent finishes are now pretty much commonplace. My question here is will we really have to worry about the mechanical finishes of most 3D printing methods, or will these finishes eventually become canon in the landscape of the near future?

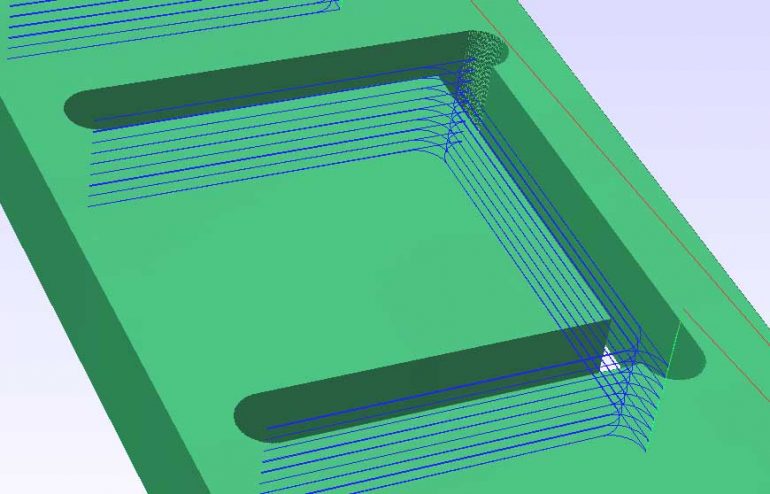

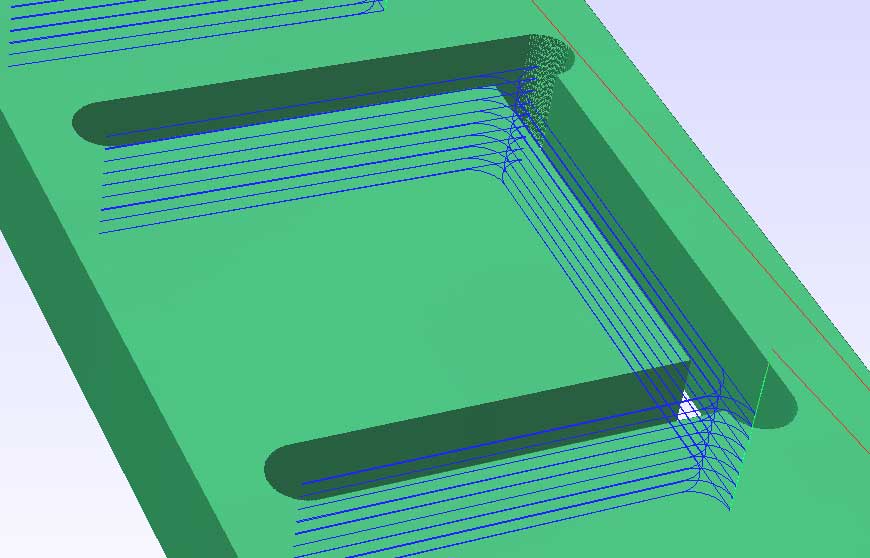

3D printing gives a lot of fabrication opportunities previously only dreamed of. There’s the possibility of new shapes as well as more mundane aspects like manufacture-ability and eventually leading to mass customization. Will the value of the ability to quickly manufacture a bespoke item offset the surface finish from the process? Would we be good with that?

Basically that trade off is the same proposition that whichever movement you’d like to use, be it Art Deco or International Style Modernism gave us at the turn of the previous century – or even the big three with hubcaps that look like expensive cast wheels.

Would you desire something so much you’re willing to give up some detail to get it? If history is a roadmap for the future, the answer is yes.