Cutting inside corners with CNC fabrication machines can be a bit tricky. Here are a few possible solutions.

We’re what’s known principally as a 2.5D fabrication company. I’m not completely sure what that means. Is that because a knee mill has a deeper Z? Or that we focus on sheet stock material? I don’t know, but what I do know is that we tend to deal with corner cutting quite a bit as it relates to the inevitable fitting of squares into circles. More specifically, the finishing of radiused inside corners. I’m sure most machining centers do as well, despite having that extra 0.5D at the ready.

To illustrate a few of the possible solutions, we took a bit of machine time to quickly cut examples in real wood. By ‘quickly,’ we really mean quick and dirty as time didn’t permit dialing in the machine or finish sanding.

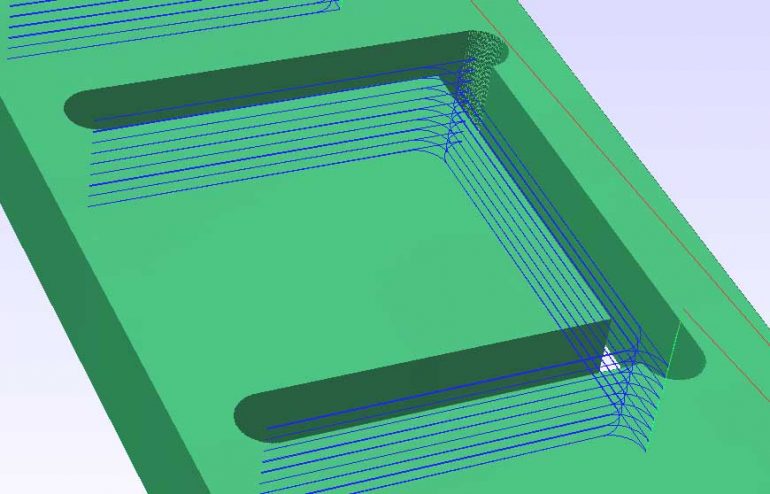

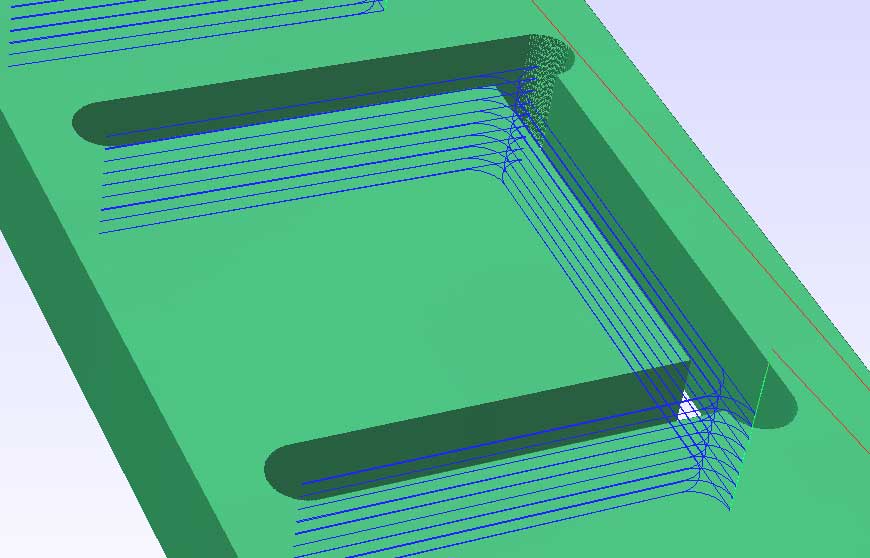

Everyone wants that perfect square inside corner in their work – maybe because it just looks crisp or perhaps they have what amounts to a tenon to fit in there. The round tooling every shop uses can’t accommodate that desire. It can get close, but you eventually end up with a radius on the inner corner like above. The smaller the bit, the less egregious the radius to be sure. With this in mind, a possible answer to the mated part issue is to simply put an outside radius on the tenon. Sometimes that’s just not in the plan.

But what are the other options? We could pick a few ways to overshoot the corner.

Pre-drilling the corners yields a corner like this. It makes room for the corners of the mated piece. If you set it up like the above drawing to the above left, you can minimize the excess of material removal. The downside is that it performs one more distinct operation in the process. It takes a bit more time and when you get charged for time on the machine it can make a difference if the volume is great enough.

Another option is to actually overshoot the corner of the rectangle. This way the excess corner material is taken out using the same tool path as the cutting of the shape. For the CNC purists it also is a bit easier on the cutting tool as the bit doesn’t perform the unsatisfactory slow to stop/direction change as seen in the radiused corners which could end up burning the work piece. The trade-off is they tend to take a bit more attention to hide in the design of the product’s assembly.

Both of these options obviously wouldn’t pass muster with classically-trained, chisel-wielding craftsmen. But then again if you make the adjustment, we can cut you a number of work pieces before any of those craftsmen can sharpen their chisels! It’s all in the design, specification and the expectations of the job. Without that specification, we’ll default to that inner radius.