I think that when you look at where to apply today’s digital fabrication capabilities, it breaks down essentially into two camps: the desire for complexity and/or for precision. In a way, these two are really intertwined but for today it’s interesting to address them as separate requests.

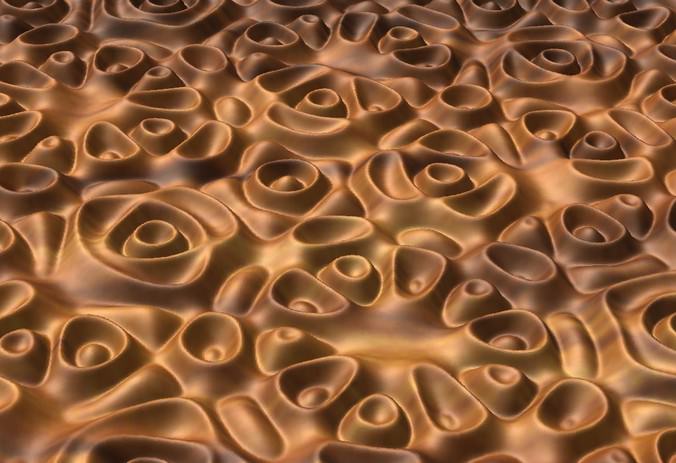

Looking at complexity, this would be the pursuit of perhaps stylistic or artistic results that may have to fall on a machine to execute for a variety of reasons. Perhaps the project requires a level of skill that’s either impossible to find or virtually impossible to fund. A good example is of a bias relief treatment for decorative panels. A machine would be much more adept at holding a continuous level of faithfulness to the design across much more vast areas than could be expected or maybe even found with conventional human craftsmen. Not that I’m knocking human craftsmen – as it’s their skill over the millennia that’s opened the door for us to even consider the sorts of projects.

The other side of digital fabrication in my opinion would be the pursuit of a sort of umbrella of precision. For this, it’s best to picture the sort of fine joinery that human craftsmen of the highest quality have produced over the centuries. What makes all this work, whether of the Eastern schools or Western, is an extreme attention to detail. That very same detail is extraordinarily difficult to perform on today’s job sites. The modern builder is hamstrung by power tools designed for speed rather than craftsmanship and these builders have to work under increasingly tight budgets and tight deadlines. This old-world craftsmanship at an architectural level is left for only the very well off to afford and even they may just not prefer to outlay the time or the costs for such work.

This is perhaps one of the best applications of digital fabrication – the application of a machine’s inherent precision coupled with a tireless speed that can make structural joinery a reality. Both of these factors also serve to push down the cost of increasing the build quality in architecture at the same time.

Both of these features of today’s digital fabrication capabilities, complexity and precision have been executed at one time or another but there’s certainly a great amount of applications that are primed for even greater penetration of the market. Coupling both of these features with a designer’s or architect’s increasing reliance on the use of CAD and BIM, the notion of applying machine’s inherent strengths into both worlds seems all but inevitable